Compression Dead-End: ACFR

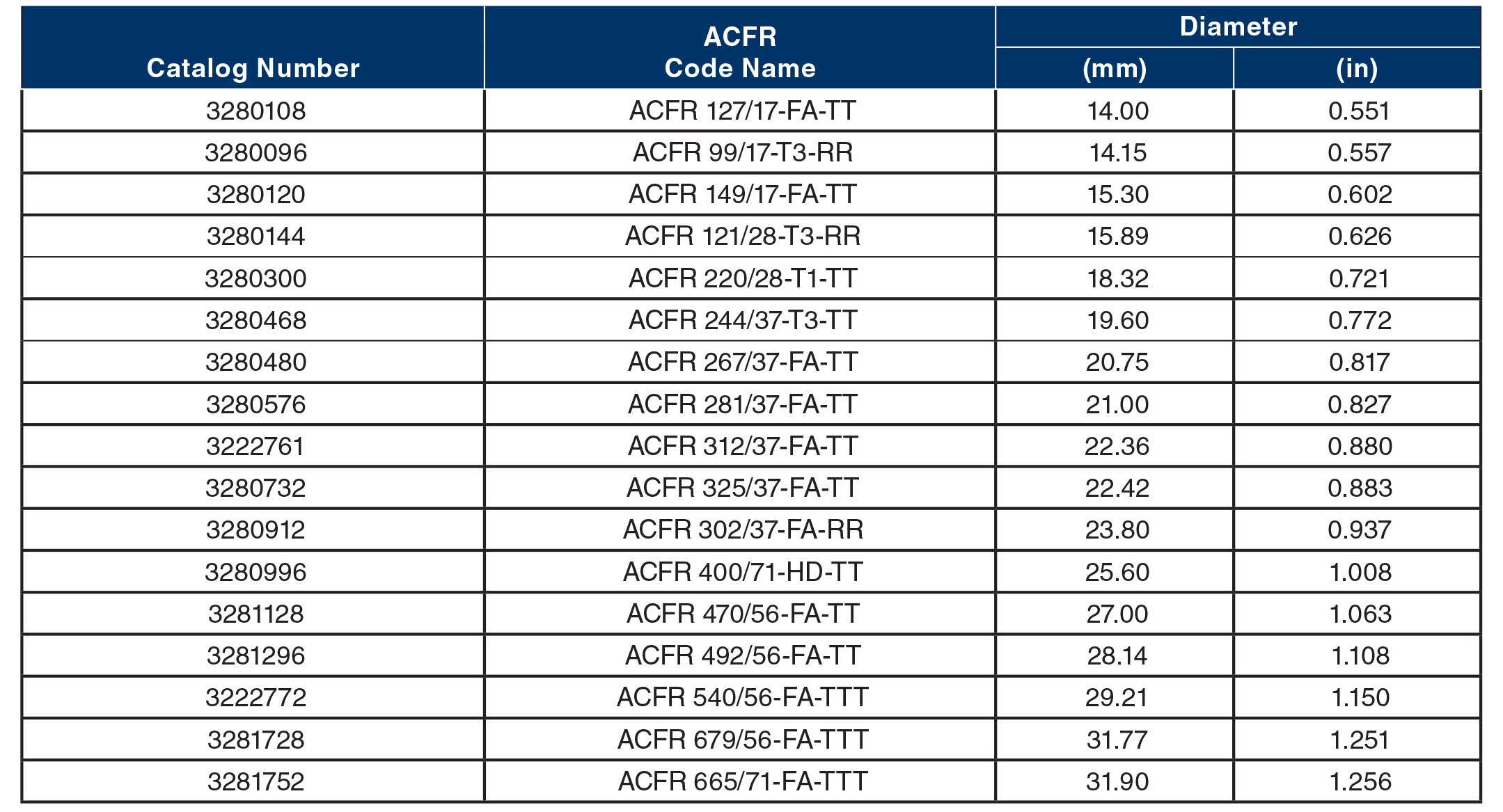

These Compression Dead-Ends are specially designed for applications on ACFR (Aluminum Conductor Fiber Reinforced) conductor only. Designs utilize a dual compression product requiring compression of a steel component around the steel core and an aluminum component around the aluminum wire OD. Compression of products can be completed with industry standard presses and dies.

- The Compression Dead-Ends are specially designed for applications on ACFR conductors.

- Design allows for continuous conductor operating temperature up to 180° C and 2-hour 200° C emergency operating temperature.

- Holding Strength: 95% or more of the conductor rated breaking strength (RBS) in accordance with ANSI C119.4 requirements for dead-end tensile strength.

- Compression of products can be completed with industry standard presses and specialty dies. Please contact PLP for information on purchasing compression dies for ACFR applications.

Includes:

- Dead-end Eye: Steel component of the dead-end assembly.

- Dead-end Body: Aluminum component of the dead-end assembly that is compressed around the OD of the conductor.

- Inner Sleeve: Provides spacing between the conductor and the dead end body to allow for compression.

- Aluminum Jumper: Aluminum body that is compressed around the OD of the conductor and bolts to the dead-end assembly.

- Hardware: nuts, bolts and washers.Galvanized steel or stainless steel option.

ACFR®is a registered trademark of Tokyo Rope

Application Procedures

SP3506-3 (Compression Dead-End)

Small Catalog

ACFR Compression Dead-End

▼

▼