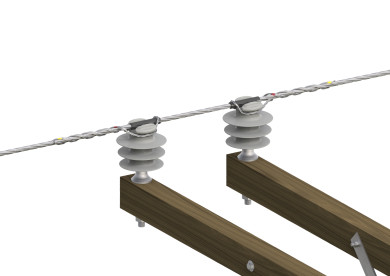

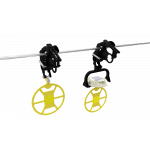

Double Support Tie

Double Side Ties, manufactured of aluminum covered steel, secure conductors on double arm construction in the side groove of interchangeable headstyle insulators and are intended for larger line angles than top groove style ties. Double Side Ties feature an elastomeric tube that surrounds the bare conductor with a resilient cushion, providing superior abrasion protection under all types of conductor motion, including low-frequency galloping and high-frequency aeolian vibration. As a result, Double Side Ties with tie tubes provide better protection than hand ties over protective rods by providing an armoring layer that eliminates abrasion damage of the conductor and insulator caused by conductor motion. This extends the life of the electrical system and reduces maintenance.

-

Applicable to interchangeable headstyle insulators - C, F, and J-Neck

-

Accommodates conductors from 0.245" - 1.240" diameter

-

Pre-contoured Tie ensures a tight fit

-

Mitigates long-term issues caused by Radio Influence Voltage (RIV)

-

Accommodates line angles up to 80-degrees (40-degrees per Insulator)

-

Exceeds NESC requirements for unbalanced load

-

Reduces or eliminates abrasion caused by vibration

-

Ideal for severe weather applications and system hardening activities

-

Resiliency of the tie protects the conductor

-

Test reports available upon request

Product Information

Double Support Tie - Catalog Pages

Installation Instructions

SP-2217 (Double Support Tie - Hairpin Style)

SP-3386 (Double Support Tie - Tabbed Style)

SP-3387 (Tabbed Style vs. Hairpin Style) Letter of Design Reinstatement

|

Diameter Range1 |

Nominal Conductor Size2 | Units per Carton | C-Neck Insulators (Black) | J-Neck Insulators (Green) | Conductor Color Code | Tie Type | ||||

| in | Catalog Number | Applied Length | Catalog Number | Applied Length | ||||||

| Minimum | Maximum | in | in | |||||||

| 9/16" R. Groove4 | ||||||||||

| 0.245 | 0.277 |

#4, 6/1, 7/1; #4, 7W Alum. Alloy |

50 | DST-0150 | 13 | DST-0350 | 14 | Orange | Tabbed | |

| 0.278 | 0.315 |

#3, 7W Alum. Alloy; #2, 7W All Alum. |

50 | DST-0151 | 13 | DST-0351 | 14 | Purple | ||

| 0.316 | 0.357 |

#2, 6/1, 7/1; #2, 7W Alum. Alloy; #1, 6/1 ACSR |

50 | DST-0152 | 14 | DST-0352 | 15 | Red | ||

| 0.358 |

0.405 |

1/0, 7W All Alum.; 1/0, 6/1 ACSR; 1/0, 7W Alum. Alloy |

50 | DST-0153 | 14 | DST-0353 | 15 | Yellow | ||

| 0.406 | 0.459 |

2/0, 7W All Alum.; 2/0, 6/1 ACSR; 2/0, 7W Alum. Alloy |

50 | DST-0154 | 15 | DST-0354 | 16 | Blue | ||

| 0.460 | 0.520 |

3/0, 7W All Alum.; 3/0, 6/1 ACSR; 3/0, 7W Alum. Alloy |

50 | DST-0155 | 16 | DST-0355 | 16 | Orange | ||

| 0.521 | 0.588 |

4/0, 7W All Alum.; 4/0, 6/1 ACSR; 4/0, 7W Alum. Alloy |

50 | DST-0156 | 17 | DST-0356 | 18 | Red | ||

| 0.589 | 0.665 |

266.8, 37W All Alum.; 266.8, 18/1 |

50 | DST-0157 | 17 | DST-0357 | 18 | Purple | ||

| 9/16" R. Groove4 | ||||||||||

| 0.666 | 0.755 | 336.4, 19W All Alum.; 336.4, 18/1; 397.5, 19W All Alum. | 50 | DST-0158 | 18 | DST-0358 | 19 | Brown | Tabbed | |

| 0.756 | 0.858 |

477, 19W, 37W All Alum.; 477, 18/1 24/7, 26/7 |

50 | DST-0159 | 20 | DST-0359 | 21 | Red | Hairpin | |

| 5/8" R. Groove4 | ||||||||||

| 0.859 | 0.968 |

556.5, 26/7; 636, 18/1; 700, 37W, 61W All Alum. |

25 | DST-0160 | 21 | DST-0360 | 22 | Blue | Hairpin | |

| 3/4" R. Groove4 | ||||||||||

| 0.969 | 1.096 |

795, 37W All Alum.; 795, 61W All Alum.; 715.5, 24/7; 795, 54/7 |

25 | DST-0161 | 22 | DST-0361 | 23 | Green | Hairpin | |

| 1.097 | 1.240 |

954, 36/1, 54/7; 1033.5, 37W, 61W All Alum. |

25 | DST-0162 | 23 | DST-0362 | 24 | Yellow | ||

|

Right-hand lay standard NOTES: 1 Diameter Range indicates the size of conductors that utilize the same tie. 2 Nominal Conductor Size indicates one or more of various conductors within each range. 3 The loop of the Double Side Tie can accommodate either C, F, or J-Neck insulators as indicated in the table. 4 For the succeeding ranges the insulator's side groove radius should be at least as large as shown above. |

||||||||||

▼

▼